コントローラー内蔵ステッピングモーター直線移動ステージ(リニアステージ)、移動量300 mm

- Integrated Controller with Keypad and Remote USB Control

- Stackable in XY, XZ, and XYZ Configurations

- Calibrated On-Axis Accuracy of <±5 µm

- Horizontal Load Capacity of 15 kg (33.1 lbs)

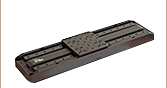

LTS300C

300 mm Translation Stage

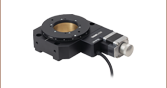

LTSP3

Right-Angle Bracket

Application Idea

Three LTS300C Stages in

XYZ Configuration, Using an

LTSP1 XY Adapter Plate and

LTSP3 Right-Angle Bracket

Please Wait

| Key Specificationsa | |

|---|---|

| Travel Range | 300 mm (11.8") |

| Horizontal Velocity (Max) | 50 mm/s |

| Vertical Velocity (Max) | 3 mm/s |

| Minimum Achievable Incremental Movementb | 0.1 µm |

| Calibrated On-Axis Accuracyc | < ±5 µm |

| Bidirectional Repeatabilityd | < ±2 µm |

| Backlashe | 2 µm |

| Load Capacity (Max) - Stage Mounted Horizontally | 15 kg (33.1 lbs) |

| Load Capacity (Max) - Stage Mounted Vertically | 4 kg (8.8 lbs) |

| Actuator Type | Stepper Motor |

| Included USB Cable Length | 1.5 m (4.9 ft) |

特長

- 最大移動量:300 mm

- ステッピングモータ用コントローラ内蔵

- 手動キーパットによる操作またはPCによるリモート操作

- 耐荷重

- 水平設置時の荷重: 15 kg

- 垂直設置時の荷重: 4 kg

- 最高速度:50 mm/s

- 双方向再現性: ±2 µm以下

- XY、XZ、XYZに構成可能

- 標準的なオプトメカニクス取付け用M6タップ穴あり

- 電源が付属

コントローラ内蔵の直線移動ステージ(リニアステージ) LTS300C/Mは、測定や検査など高耐荷重かつ高分解能が必要な用途向けの製品です。 直線移動量は300 mmで、水平に設置した場合の耐荷重は15 kg、垂直に設置した場合は4 kgです。各ステージの確度(軸上)は、製品の校正ファイルを当社のKinesisソフトウェアに使用した場合で、±5.0 µm以内となります。ステッピングモータ設計のため、ステージに電力供給がされていない時には、プラットフォームの位置は(DCサーボモータの移動ステージとは異なり)固定されます。

Click to Enlarge

手動およびPCによるリモート操作が可能なコントローラ内蔵

| Motorized Linear Long-Travel Stages | |

|---|---|

| 100 mm | Stepper |

| DC Servo | |

| 150 mm | Stepper |

| Stepper with Integrated Controller | |

| 220 mm | DC Servo |

| 300 mm | Stepper with Integrated Controller |

| DC Servo | |

| 600 mm | DC Servo |

| Optical Delay Line Kits | |

| Other Translation Stages | |

ステージLTS300C/Mには、PCを使ってのリモート操作や、コントローラのキーパッド上のボタンまたは速度ポテンショメータでの手動操作によって制御で きる電子コントローラが内蔵されています(左の写真参照)。 パラメータ設定はPC上で行い、その後ユニット内の不揮発性メモリに保存できます。 従って、次回ユニットが作動したときに、(PCを接続しなくても)この設定は自動的に適用されます。 この機能は、ステージをPCやUSB接続を使わずに手動で操作する場合に特に便利です。

ステージは軽量でコンパクトな設計で、どの位置にいる場合でもぶれない性能を備えています。 高耐荷重アルミニウム構造と40.5 mmの高さの移動プラットフォームは、狭いスペースでの用途に適しています。 内蔵された磁気リミットスイッチにより、両端おけるオーバードライブを防ぐことができます。 精密研磨された親ネジにより滑らかでノイズのない運動が可能です。 ステージに付属している電源は入力電圧90~264 VAC(47~63 Hz)に対応可能で、日本国内仕様の電源コードが付属します。

コントローラ内蔵で移動距離150 mmの直線移動ステージLTS150C/Mもご用意しております。

校正ファイル

各直線移動ステージLTS300C/Mは製造時に校正されています。校正を行うと、コントローラによりシステムに内在する機械的誤差を補正されます。 送りネジやリンク機構などの機械部品は、一定の許容差をもって製造されます。 このような機械的誤差は、指令位置から実際の位置までの移動量誤差をもたらします。 しかしこのような誤差量には再現性があるため、Kinesisソフトウェアと付属の校正ファイルを使用すれば補償することが可能です。 校正ファイルは、ユーザ入力された位置情報を、ソフトウェアが機械的な移動量に変換するために使用されます。 校正ファイルは下の型番横の赤いアイコン ![]() )

)

校正ファイルの使用は任意です。使用しなくてもステージの再現性と分解能に影響はありませんが、確度を向上する補正が実行されません。 各ステージは工場で校正済みで、校正ファイルを使用しなくても典型的な確度は47 µm(典型値)となります。

ステージの組合せ

XY構成をお考えの場合、リニア式位置決めステージLTS300C/MやLTS150C/M(移動量150 mm)を自由に組み合わせ、XYアダプタープレートLTSP1/M(別売り)を使用して上下に取り付けることができます。 XZやXYZ構成には、ステージLTS300C/Mを垂直方向に取り付けられる当社のZ軸ブラケットLTSP3/Mがお使いいただけます。ミリ規格のタップ穴付きのステージやアダプタは、ミリ規格のステージやアダプタにのみ取り付け可能ですのでご注意ください。

ソフトウェア

当社のKinesis®ソフトウェアパッケージは、マルチチャンネルコントローラ、ラックベースのコントローラ、小型で光学テーブルに取付けが可能なK-Cube®コントローラなど、当社の幅広いモーションコントローラを駆動できます。1つに統合されたソフトウェアによって、ステージLTS300/Mをベンチトップ、テーブルトップまたはラックベースのあらゆるコントローラとシームレスに組み合わせることが可能です。

| Stage Specifications | ||

|---|---|---|

| Translation | ||

| Travel Range | 300 mm (11.8") | |

| Bidirectional Repeatability | < ±2 µm | |

| Backlash | 2 µm | |

| Maximum Velocitya | 50 mm/s Horizontal, 3 mm/s Vertical | |

| Velocity Stability | ±1 mm/s | |

| Maximum Accelerationa | 50 mm/s2 Horizontal, 5 mm/s2 Vertical | |

| Accuracy | ||

| Min Achievable Incremental Movementb | 100 nm | |

| Min Repeatable Incremental Movementc | 4 µm | |

| Calibrated On-Axis Accuracy | < ±5 µm | |

| Max Percentage Accuracyd | 0.12% | |

| Home Location Accuracy | ±0.6 µm | |

| Pitche | < 0.022° (384 µrad) | |

| Yawe | < 0.06° (1047 µrad) | |

| Load Capacity | ||

| Horizontal Load Capacity | Max: 15 kg (33.1 lbs) Recommended: < 12 kg (26.5 lbs) | |

| Vertical Load Capacity | Max: 4 kg (8.8 lbs) | |

| General | ||

| Included USB Cable Length | 1.5 m (4.9 ft) | |

| Weight | 3.0 kg (6.61 lbs) | |

| Dimensions (W x D x H) | 100.0 mm x 500.0 mm x 40.5 mm (3.94" x 19.69" x 1.59") | |

| Electrical Specifications | |

|---|---|

| Motor Specifications | |

| Step Angle | 1.8° (50 Poles and ±2 Phases for 360° Divided by 200) |

| Step Accuracy | 5% |

| Rated Phase Current | 0.85 A |

| Phase Resistance | 5.4 Ω |

| Phase Inductance | 5.6 mH |

| Holding Torque | 20 N•cm |

| Detent Torque | 2.0 N•cm |

| Operating Temperature | -20 to 40 °C (Motor Specification Only) |

| Controller Specifications | |

| Microsteps per Full Step | 2048 |

| Microsteps per Revolution of Motor | 409,600 (for 200 Step Motor) |

| Motor Drive Voltage | 24 V |

| Motor Drive Power | 12.5 W (Avg.) Up to 25 W (Peak) |

| Motor Speeds | Up to 3000 RPM (200 Full Step Motor) |

| Input Power Requirements | |

| Voltage | 24 VDC |

| Power | 25 W (Peak) |

| Power Supply Requirements | 90 - 264 VAC (47 - 63 Hz) |

注意

PC接続

USB B型

2 m 長のUSBのB型-A型変換ケーブルが付属します。

ソフトウェア

Kinesisバージョン1.14.53

このKinesisソフトウェアパッケージには、当社のKinesisシステムコントローラを制御するためのGUIが含まれています。

下記もご用意しております。

- 通信プロトコル

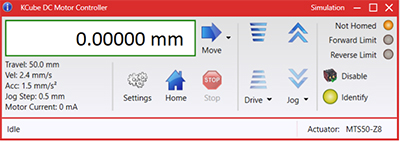

Figure 58A KinesisソフトウェアのGUI画面

当社のKinesisソフトウェアパッケージを用いて、当社の様々なモーションコントローラを駆動することができます。このソフトウェアは小型で低出力のシングルチャンネルドライバ(K-Cube®など)から、高出力でマルチチャンネルのベンチトップ型ユニットやモジュール型の19インチラックナノポジショニングシステム(ラックシステムMMR60x)まで、当社Kinesisシリーズの様々なモーションコントローラの制御用にご使用いただけます。

Kinesisソフトウェアでは.NETコントロールを使用できるため、最新のC#、Visual Basic、LabVIEW™、あるいはその他の.NET対応言語を使用してカスタムプログラムを作成することができます。.NETフレームワークやAPIの使用を想定していないアプリケーションのために、ローレベルのDLLライブラリも含まれています。中央シーケンスマネージャ(Central Sequence Manager)は、当社のすべてのモーションコントロール用ハードウェアの統合と同期の機能をサポートしています。

この共通のソフトウェアプラットフォームにより、ユーザは単一のソフトウェアツールを習得するだけで、あらゆるモーションコントロールデバイスを1つのアプリケーション内で組み合わせて使用することができます。このように1軸システム用から多軸システム用までのあらゆるコントローラを組み合わせ、それら全てを1台のPCの統合されたソフトウェアインターフェイスから制御できます。

このソフトウェアパッケージには2つの使い方があります。1つはGUI(グラフィカルユーザーインターフェイス)ユーティリティを用いる方法で、コントローラの到着後すぐに直接的な操作と制御を行なうことができます。もう1つは一連のプログラミングインターフェイスを用いる方法で、ご希望の開発言語によりカスタム仕様の位置決めやアライメント用のプログラムを簡単に作成することができます。

| Posted Comments: | |

Richard Harris

(posted 2023-06-28 11:49:14.65) I am looking at the LTS300C and would like to know if this has an optical encoder to measure distance moved? do'neill

(posted 2023-07-04 10:06:14.0) Response from Daniel at Thorlabs. The LTS300C does not have an optical encoder, the stage counts steps from the home position. Ahmad Rafsanjani

(posted 2023-01-30 08:11:47.347) Hi there,

We have a LTS300 linear stage and we would like to control it from MATLAB.

We found some examples on the web for other models but we could not adjust it to LTS300. Can you please provide a MATLAB code for this purpose?

Thanks,

Ahmad Rafsanjani

Associate Prof, SDU Biorobotics, Denmark do'neill

(posted 2023-01-30 12:16:29.0) Response from Daniel at Thorlabs. Thank you for your feedback, we have reached out to you directly to provide this script. user

(posted 2022-09-19 17:10:36.03) We are using LTS300/M and found a problem with parameter "steps per rev" in the software APT User. When the "steps per rev" was set to 800 (the default value is 200), the real motion distance of the stage is 4 times that of setting value. For example, a moving of 5 mm results in a real moving of 20 mm. DJayasuriya

(posted 2022-09-27 04:15:32.0) Thank you for your feedback, we have reached out to you directly to resolve the issue. Zahra Navabi

(posted 2022-07-29 08:01:46.077) Hi,

I purchased the LTS300/M stage about 2 months ago. The actuator makes a very loud noise when it gets to about 100 mm distance. Reducing the movement speed was helping at first, but now it's always very loud when it gets there. I have tried lubricating the lead screw, but it didn't help. I would be thankful if you could help me with that. I really need the actuator to be in my system, and it will almost shut down the project if I need to send it back. DJayasuriya

(posted 2022-08-01 08:17:59.0) Thank you for your inquiry. we will get in touch with you directly to resolve this. user

(posted 2022-06-23 12:59:30.963) Hello,

Two questions:

it is possible to operate the stage inverted ? Means, can the items to be moved hang down from the stage ? If so, what would be the maximum weight ?

Can you offer a LAN - interface for computer control ?

Thanks

Stephen cwright

(posted 2022-06-24 04:41:17.0) Response from Charles at Thorlabs: Thank you for your query. Unfortunately we can not provide this device with an ethernet connection. While we have not characterised a maximum load for this stage when used inverted we will reach out to discuss your application and assess whether it will meet your needs. user

(posted 2022-06-09 08:48:57.93) Is it possible tp program these devices in Kinesis to move in a circle motion repeatedly (with increasing or decreasing radius)? If so, do you happen to have such sequence programmed already that you could send me?

Thanks cwright

(posted 2022-06-09 11:02:39.0) Response from Charles at Thorlabs: Thank you for contacting us. These devices are not suited to this application. You could create an array of positions for both an X and Y axis, which would move the top plate to positions on a circumference but unfortunately you cannot command the LTS to move between two positions with a sinusoidal varying velocity, which would be required on both axes to traverse a constant circle. Anton Bäck

(posted 2022-04-26 11:50:46.207) Hello Thorlabs,

I am working with your LTS300 device to work together with our API in .NET but I have a small issue I was hoping you could assist me with. On a few occasions, the motor has initiated an "Offset" sequence during an exception leading to the home position being transferred to the other side of the ledge and not close to the motor. While this has only happened twice and I've tried to re-trigger this issue so that I can develop an align function to prevent this, somehow it doesn't want to reset it. Do you have any idea on how to trigger this issue so that it is troubleshootable or if their is any fix to this issue which you could provide me with? Thanks in advance, Anton Bäck do'neill

(posted 2025-02-21 07:33:53.0) Thank you for reaching out. We have reached out directly to help support your troubleshooting. yamit geron

(posted 2022-03-16 22:17:36.127) Greetings ,

I got the product and power supply but I do not understand how to assemble it, came in two parts.

I would love guidance.

Thanks Yamit Geron DJayasuriya

(posted 2022-03-17 07:46:08.0) Thank you for your inquiry. On the LTS next to the USB port you should be able to plug the power supply in. Alexander Dumont

(posted 2021-06-16 10:58:38.477) What power unit do we need for this device. I have a LTS300, with no power supply, and I would like to know what power supply is needed.

Thanks

Alex YLohia

(posted 2021-08-27 02:38:40.0) The power requirements are listed on the "Specs" tab on the product page. We do not recommend using a third-party PSU as we cannot guarantee performance. We can, however, supply you a replacement component PSU if interested. Mikael Malmstrom

(posted 2021-06-10 09:43:12.833) I'm trying to communicate with my LTS300/M with Matlab but I'm geting this error when running the sample code "APT_GUI.m". Anny suggestions as of what to try?

Warning: ACTXCONTROL will be removed in a future release. For more information see UI Alternatives for MATLAB Apps on mathworks.com.

> In actxcontrol (line 61)

In APT_GUI (line 13)

Error using actxcontrol_internal

Control creation failed. Invalid ProgID 'MGMOTOR.MGMotorCtrl.1'.

Error in actxcontrol (line 62)

[varargout{1:nargout}] = actxcontrol_internal(varargin{:});

Error in APT_GUI (line 13)

h = actxcontrol('MGMOTOR.MGMotorCtrl.1',[20 20 600 400 ], f); jcater

(posted 2021-06-11 06:19:11.0) Response from Jack at Thorlabs: Thank you for your inquiry. The first warning is displayed as Matlab are removing support for ActiveX controls in future releases.

The error 'Control creation failed. Invalid ProgID 'MGMOTOR.MGMotorCtrl.1' most typically occurs because the ActiveX control is not present and registered on the target machine. However I will reach out to you to help troubleshoot further. Luc Stevens

(posted 2020-11-16 10:29:07.393) I would like to understand the mechanical safety risk for this item (LTS300). What would happen if a finger is trapped in between the moving stage. How severely would the injury be? DJayasuriya

(posted 2020-11-17 04:20:06.0) Thank you for your inquiry. The LTS leadscrew is directly connected to the motor making it relatively easier to stall. However different velocities would have different forces to stall. A peak force meter would give prices measurement of force to stall. Depending on how fast the moving world is traveling we would say it could injure a finger. We will get in touch with you directly with these measurements rubsanmi

(posted 2017-05-15 16:42:02.71) I am experiencing some troubles when using these motors alongside LabVIEW. The driver version I use is the latest (3.21.0). Nevertheless, some times I got from LabVIEW the following error:

Error; [Code = 10055]; [MG17Comms.DLL] Internal

Description: USB Comms Error

Notes: A USB communications error has occurred.

Extra info: FT_IO_ERROR. A USB communication problem has occurred with this controller. Communication to this controller is suspended. The software should be closed and the controller powered off and on to try re-establishing USB communication.

I attach a link to a photo of the error: http://imgur.com/a/JJ750

I have disabled all options that turned off the screen or sleep the computer. I am using Windows 10 with LabVIEW 2016 but same problem appears with Windows XP and LabVIEW 2010 (and LabVIEW driver version 1.0.2). bwood

(posted 2017-05-17 09:12:28.0) Response from Ben at Thorlabs: I am sorry to hear about your difficulties here. This error is usually indicative of a hardware fault with the USB connection. I will be in contact with you directly to troubleshoot this issue. gwenael.gaborit

(posted 2016-12-21 05:13:34.6) I didn t find any application software for Linux OS... tfrisch

(posted 2016-12-22 06:06:59.0) Hello, thank you for contacting Thorlabs. Unfortunately, we have not been able to develop software explicitly for Linux, but you can use the communications protocol found below. I will reach out to you directly as well.

https://www.thorlabs.com/Software/Motion%20Control/APT_Communications_Protocol_Rev_19.pdf jasonmance2

(posted 2016-11-10 19:14:55.897) May I have the low level communications protocol so that I can achieve direct serial communication with the LTS300? I would like to use an Arduino to control the stage. bhallewell

(posted 2016-11-11 04:27:20.0) Response from Ben at Thorlabs: You can find our protocol manual within the 'Communications Protol' tab in the following link.

https://www.thorlabs.de/software_pages/ViewSoftwarePage.cfm?Code=Motion_Control julien.lancelot

(posted 2016-02-08 13:00:31.477) Hi there!

Do you have some API I could use to drive the motion controller with Linux?

Thanks!

Lancelot msoulby

(posted 2016-02-08 10:18:17.0) Response from Mike at Thorlabs: It is possible to use low level direct serial communications with the LTS if you are using a Linux OS. I have contacted you directly with the latest version of the low level communications protocol for our motion control controllers for your information. perttu.sipila

(posted 2015-11-11 05:53:43.36) Hi,

First C API function which is recognized from DLL is.

ISC_API short __cdecl ISC_MoveRelativeDistance(const char * serialNo);

I used it like below.

short ok = ISC_SetMoveRelativeDistance(serialNo_LTS150, -50000);

ok = ISC_SetMoveRelativeDistance(serialNo_LTS300, -50000);

ok = ISC_MoveRelativeDistance(serialNo_LTS150);

ok = ISC_MoveRelativeDistance(serialNo_LTS300);

and the compiler say:

Error 5 error LNK2019: unresolved external symbol __imp__ISC_MoveRelativeDistance

??

Perttu perttu.sipila

(posted 2015-11-11 04:06:17.953) Hi,

I am still struggling with LTS devices. I still cannot use them via C API. I am just wondering if you had a full example code how to e.g. initialize and move the stage back and forth?

The example codes in your C API help seem to be a bit old and they are just parts of some bigger full code.

I can open and use the API commands but the stages do not fully work. I think the problem would be in the initialization and my question regarding that is Should I initialize stages by using Kinesis software or do I have to do it completely in my C++ software?

The API commands are not clearly documented. E.g LoadSettings, should I use it. Does this load something initialized with Kinesis software?

Perttu perttu.sipila

(posted 2015-11-10 04:19:24.863) Hi,

I managed to open LTS device (ISC_Open). I learnt that I had to say TLI_BuildDeviceList before that! But the next the program falls down (unhandled exception) when I use the TLI_GetDeviceInfo function in the following way (copied from your example)??

short n = TLI_GetDeviceListSize();

char serialNos[100]; TLI_GetDeviceListByTypeExt(serialNos, 100, 45); // output list of matching devices

char *p = strtok(serialNos, ",");

while(p != NULL)

{

short ok = ISC_Open(p);

TLI_DeviceInfo deviceInfo; // get device info from device

TLI_GetDeviceInfo(p, &deviceInfo); // get strings from device info structure

Best, Perttu msoulby

(posted 2015-11-10 11:03:13.0) Response from Mike at Thorlabs: Thank you for your feedback, we will contact you directly to help you troubleshoot this enquiry. For further Kinesis troubleshooting please email techsupport.uk@thorlabs.com perttu.sipila

(posted 2015-11-09 08:26:05.373) Hi,

I downloaded h and lib files for LTS stages from your dropbox. I built a simple program according to your sample codes and a few lines is depicted below. I can built the project without errors. In addition my stages can be controlled via Kinesis software which shows the serial numbers used below.

char* serialNo_LTS150 = "45863013";

char* serialNo_LTS300 = "45863493";

short ok = ISC_Open(serialNo_LTS150);

short ok2 = ISC_Open(serialNo_LTS300);

My questions are:

Why I cannot open the LTS stages? The error code is 1 in both cases. What does that error code mean?

Best regards, Perttu perttu.sipila

(posted 2015-11-03 11:04:38.773) Hi,

Still one question more.. As I did not manage to add controls onto visual studio c++ console application..

Bit unsatisfied that also ActiveX component did not locate in the list of ActiveX components in Visual Studio MFC application.

That is stupid that there is mensioned how easy the device is to integrate. There are good video tutorials and much text but they do not work for me. In earlier message I mensioned that I have installed APT and Kinesis software for 64-bit windows and through them I do can easily control my LTS150 and LTS300 devices..

Perhaps if I fight a couple of days I may understand why but now I am a bit unsatisfied. msoulby

(posted 2015-11-05 03:51:20.0) Response by Mike at Thorlabs: We will contact you directly with further information. perttu.sipila

(posted 2015-11-03 10:46:41.987) Hi,

#include "Thorlabs.MotionControl.IntegratedStepperMotors.h"

where is this file? I have installed APT and Kinesis software 64-bit versions. In addition, where is a corresponding.lib file ??? msoulby

(posted 2015-11-04 10:29:50.0) Response from Mike at Thorlabs: We have emailed you directly with the .h file. This was unfortunately missed from the installation and will be added to the next update for the kinesis software. perttu.sipila

(posted 2015-11-03 10:42:44.25) Hi,

I purchased LTS150 and LTS300 and bit satisfied that found difficult to integrate onto my environment. Yes, APT and Kinesis software work, but I cannot find simple h files that I could somehow append dll files onto C console application. This is mensioned to be possible and there is even an example code, but e.g. h file to be included resides not in my computer. stephanealbon

(posted 2015-07-28 12:48:54.34) Dear Sir/Madame, I am writing to you due to communication issues with the LTS300 motorized stage when using Labview ActiveX controls. Is there any one I can talk about this in more details by email ? and get some help ? msoulby

(posted 2015-07-28 06:09:56.0) Response from Mike at Thorlabs: I have contacted you directly to discuss the problems you are having communicating with the LTS300 stage in more detail. b.cichy

(posted 2014-12-08 13:56:41.113) Dear Sir/Madame,

I am writing to you due to technical issue with the LTS300 motorized stage. I have bought one of the LTS300 stages and have found some problems with programming the stage using the APT software. I am writing my software using the C# .NET and it is really uncomfortable to me to use the COM based ActiveX controls. I have found on your webpage that it is possible to use classic .dll library to communicate with the stage. However such information is on the website I couldn’t find the file after installing the APT package.

Is it possible to get the standard .DLL file for the LTS300? It is more beneficial to me to write a .NET wrapper than use the ActiveX controls.

I am looking to hear from you.

Sincerely yours

Bartłomiej Cichy msoulby

(posted 2014-12-09 05:21:18.0) Response from Mike at Thorlabs: Yes we have an APT DLL pack that we will send you which can be used if you do not wish to use ActiveX controls. I have contacted you will the files and further details. xi.wang

(posted 2014-10-16 05:22:58.89) how do I enable different channels for different stages? We have two LTS300/M, we'd like to have them move simultaneously. thanks, rcapehorn

(posted 2014-10-21 04:58:52.0) Response from Rob at Thorlabs: Thank you for your feedback. To control multiple channels at once, the use of third party software will be needed. Examples of such software include LabVIEW and MATLAB. I will contact you by email to further clarify this. |

電動リニアステージ

電動の直線移動ステージとしては、ピエゾ駆動の20 µm移動ステージからダイレクトドライブ方式の600 mm移動ステージまで、様々な最大移動量の製品をご用意しております。ステージの多くは、それらを用いてXY軸やXYZ軸などの多軸ステージを構築することができます。ファイバ結合用としては、多軸ステージのページをご覧ください。標準の電動ステージを用いるよりも精密な調整が可能です。直線移動ステージのほかに、電動の回転ステージおよびゴニオステージもご用意しております。また手動移動ステージもございます。

ピエゾステージ

これらのステージでは、様々な駆動機構にピエゾ素子が組み込まれています。ステージORIC®シリーズでは、「スティック-スリップ」と呼ばれる摩擦特性を利用したピエゾ慣性アクチュエータが用いられており、それにより長い移動距離が得られています。移動ステージNanoflex™シリーズは、手動アクチュエータに加えて標準的なピエゾアクチュエータが用いられています。ステージElliptec®シリーズでは共振ピエゾモータが用いられており、共振に伴うモータ先端の楕円形の動きで可動プラットフォームを押したり引いたりします。Z軸ステージLPS710E/Mにはピエゾ移動に対する機械的な増幅機構が組み込まれており、またそれに適したコントローラが付属しています。

| Piezoelectric Stages | ||||

|---|---|---|---|---|

| Product Family | ORIC® PDXZ1 Closed-Loop 4.5 mm Vertical Stage | ORIC® PD2 Open-Loop 5 mm Stage | ORIC® PDX2 Closed-Loop 5 mm Stage | ORIC® PDX4 Closed-Loop 12 mm Stage |

| Click Photo to Enlarge |  |  |  |  |

| Travel | 4.5 mm | 5 mm | 12 mm | |

| Speed | 1 mm/s (Typ.)a | 10 mm/s (Typ. Max)b | 8 mm/s (Typ.)c | 15 mm/s (Typ.)a |

| Drive Type | Piezoelectric Inertia Drive | |||

| Possible Axis Configurations | Z | X, XY, XYZ | ||

| Mounting Surface Size | 45.0 mm x 42.0 mm | 13.0 mm x 13.0 mm | 13.0 mm x 23.0 mm | |

| Additional Details | ||||

| Piezoelectric Stages | |||||||

|---|---|---|---|---|---|---|---|

| Product Family | ORIC® PD1 Open-Loop 20 mm Stage | ORIC® PD1D Open-Loop 20 mm Monolithic XY Stage | ORIC® PDX1 Closed-Loop 20 mm Stage | ORIC® PDX1A Closed-Loop 20 mm Stage Low-Profile | ORIC® PD3 Open-Loop 50 mm Stage | ORIC® PDX3 Closed-Loop 50 mm Stage | |

| Click Photo to Enlarge |  |  |  |  |  |  | |

| Travel | 20 mm | 50 mm | |||||

| Speed | 3 mm/s (Typ. Max)a | 20 mm/s (Typ. Max)c | 10 mm/s (Typ.)b | 10 mm/sd | 10 mm/s (Typ. Max)b | ||

| Drive Type | Piezoelectric Inertia Drive | ||||||

| Possible Axis Configurations | X, XY, XYZ | XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | |

| Mounting Surface Size | 30 mm x 30 mm | 80 mm x 30 mm | |||||

| Additional Details | |||||||

| Piezoelectric Stages | |||||||

|---|---|---|---|---|---|---|---|

| Product Family | Nanoflex™ 20 µm Stage with 5 mm Actuator | Nanoflex™ 25 µm Stage with 1.5 mm Actuator | Compact Modular XRN25X 25 mm Stage | Modular XR25X 25 mm Stage | Elliptec® 28 mm Stage | Elliptec® 60 mm Stage | LPS710E 1.1 mm Vertical Stage |

| Click Photo to Enlarge |  |  |  |  |  |  |  |

| Travel | 20 µm + 5 mm Manual | 25 µm + 1.5 mm Manual | 25 mm | 28 mm | 60.0 mm | 1.1 mm | |

| Maximum Velocity | - | ≤3.6 mm/mina | 180 mm/s | 90 mm/s | - | ||

| Drive Type | Piezo with Manual Actuator | Piezoelectric Inertia Drive | Resonant Piezoelectric Motor | Amplified Piezo | |||

| Possible Axis Configurations | X, XY, XYZ | X, XY, YZ, XZ, XYZ | X | Z | |||

| Mounting Surface Size | 75 mm x 75 mm | 30 mm x 30 mm | 85.0 mm x 50.7 mm | 110.0 mm x 75.7 mm | 15 mm x 15 mm | 21 mm x 21 mm | |

| Additional Details | |||||||

ステッピングモーターステージ

こちらの移動ステージは脱着型あるいは内蔵型のステッピングモータを用いており、また300 mmまでの長い移動量が可能です。これらのステージの多くは多軸移動機能を有していたり(PLSXY)、あるいは多軸ステージを組み立てることが可能であったりします(PLSX、クイック接続型XR25シリーズ、LNRシリーズ、NRTシリーズ、LTSシリーズ)。ステージMLJ150/Mは高荷重にも対応する垂直移動ステージです。

| Stepper Motor Stages | |||||

|---|---|---|---|---|---|

| Product Family | MVSN1(/M) 13 mm Vertical Stage | PLS Series 1" Stages | Modular XR25 Series 25 mm Stage | LNR Series 25 mm Stage | LNR Series 50 mm Stage |

| Click Photo to Enlarge |  |  |  |  |  |

| Travel | 13 mm | 1" (25.4 mm) | 25 mm | 25 mm | 50 mm |

| Maximum Velocity | 5.0 mm/s | 7.0 mm/s | 2.0 mm/s | 2.0 mm/s | 50 mm/s |

| Possible Axis Configurations | Z | X, XY | X, XY, YZ, XZ, XYZ | X, XY, XYZ | X, XY, XYZ |

| Mounting Surface Size | 24.5 mm x 50.0 mm | 3" x 3" (76.2 mm x 76.2 mm) | 110.0 mm x 75.7 mm | 60 mm x 60 mm | 100 mm x 100 mm |

| Additional Details | |||||

| Stepper Motor Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | NRT Series 100 mm Stage | NRT Series 150 mm Stage | LTS Series 150 mm Stage | LTS Series 300 mm Stage | MLJ250 50 mm Vertical Stage | |

| Click Photo to Enlarge |  |  |  |  |  | |

| Travel | 100 mm | 150 mm | 150 mm | 300 mm | 50 mm | |

| Maximum Velocity | 30 mm/s | 50 mm/s | 3.0 mm/s | |||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | Z | |||

| Mounting Surface Size | 84 mm x 84 mm | 100 mm x 90 mm | 148 mm x 131 mm | |||

| Additional Details | ||||||

DCサーボモーターステージ

脱着型あるいは内蔵型のDCサーボモータを用いた直線移動ステージをご用意しております。これらのステージは薄型で、多軸ステージの構築が可能です。

| DC Servo Motor Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | MT Series 12 mm Stages | PT Series 25 mm Stages | Compact Modular XNR25X 25 mm Stage | Modular XR25X 25 mm Stage | M30 Series 30 mm Stage | M30 Series 30 mm Monolithic XY Stage |

| Click Photo to Enlarge |  |  |  |  |  |  |

| Travel | 12 mm | 25 mm | 25 mm | 30 mm | ||

| Max Speed | 2.6 mm/s | 2.6 mm/sa | 2.4 mm/s | |||

| Possible Axis Configurations | X, XY, XYZ | X, XY, YZ, XZ, XYZ | X, Z | XY, XZ | ||

| Mounting Surface Size | 61.0 mm x 61.0 mm | 101.6 mm x 76.2 mm | 85.0 mm x 50.7 mm | 110.0 mm x 75.7 mm | 115.0 mm x 115.0 mm | |

| Additional Details | ||||||

| DC Servo Motor Stages | |||||

|---|---|---|---|---|---|

| Product Family | MTS Series 25 mm Stage | MTS Series 50 mm Stage | MTS Series 100 mm Stage | M150 Series 150 mm XY Stage | KVS30 30 mm Vertical Stage |

| Click Photo to Enlarge |  |  |  |  |  |

| Travel | 25 mm | 50 mm | 100 mm | 150 mm | 30 mm |

| Max Speed | 2.4 mm/s | X-Axis: 170 mm/s Y-Axis: 230 mm/s | 8.0 mm/s | ||

| Possible Axis Configurations | X, XY, XYZ | XY | Z | ||

| Mounting Surface Size | 43.0 mm x 43.0 mm | 272.4 mm x 272.4 mm | 116.2 mm x 116.2 mm | ||

| Additional Details | |||||

ダイレクトドライブステージ

こちらの薄型ステージにはブラシレスDCサーボモータが内蔵されており、バックラッシュの無い高速移動が可能です。電源が入ってないときは、ステージのプラットフォームにはほとんど慣性が無く、実質的にフリーラン状態になります。そのため電源が入ってないときにステージのプラットフォームが定位置に留まる必要のある用途には適していません。これらのステージを垂直方向に取付けることは推奨しません。

| Direct Drive Stages | |||||

|---|---|---|---|---|---|

| Product Family | DDS Series 50 mm Stage | DDS Series 100 mm Stage | DDS Series 220 mm Stage | DDS Series 300 mm Stage | DDS Series 600 mm Stage |

| Click Photo to Enlarge |  |  |  |  |  |

| Travel | 50 mm | 100 mm | 220 mm | 300 mm | 600 mm |

| Maximum Velocity | 500 mm/s | 300 mm/s | 400 mm/s | 400 mm/s | |

| Possible Axis Configurations | X, XY | X, XY | X | X | |

| Mounting Surface Size | 60 mm x 52 mm | 88 mm x 88 mm | 120 mm x 120 mm | ||

| Additional Details | |||||

ステージLTS300C/Mの移動量は300 mmで、ステッピングモータならびにコントローラが内蔵されています。 コントローラは手動のキーパッドでの操作およびPCによるリモート操作が可能です。 可動式プラットフォームに25.0 mm間隔で開いている16個のM6タップ穴を利用して、オプトメカニクスを直接取り付けることができます。

Click to Enlarge

ブラケットLTSP3(/M)とプレートLTSP1(/M)を使用してステージLTS300C(/M)を3つ取り付けてXYZ構成を構築

Click to Enlarge

ブラケットLTSP3(/M)を使用してステージLTS300C(/M)を2つ取り付けてXZ構成を構築

- ステージLTS300C/Mを取り付けてXZならびにXYZ構成を構築

- 右利きまたは左利き用でステージに取り付け可能

- ブレッドボードへの直接取り付けは不可(下記参照)

直角ブラケットLTSP3(/M)を用いて、ステージLTS300C/M)を右写真のように垂直(Z軸)方向に取り付けることができます。 アダプタープレートLTSP1/M(別売り)と直角ブラケットLTSP3/Mを使用すれば、XYZ構成を構築可能です。

このアダプタはブレッドボードに直接取り付けられる設計にはなっておりませんのでご注意ください。 垂直ステージの底部はアダプタの台座を超えて可動するため、ステージに適切な隙間を確保するため、アダプタをテーブルの上方に十分に上げて設置してください。

Products Home

Products Home

ズーム

ズーム

ステッピングモータ移動量300 mm (Ctrl内蔵)

ステッピングモータ移動量300 mm (Ctrl内蔵)