10 mm Miniature Linear Translation Stage, Vacuum Compatible

- 10 mm Travel Provided by Either Side- or End-Mounted Actuators

- Crossed-Roller Bearings for Superior Angular Deviation and Load Capacity

- Vacuum Compatible Down to 10-5 Torr at 25 °C Without Bake Out

- Stages Ship with Individual Test Data Sheets

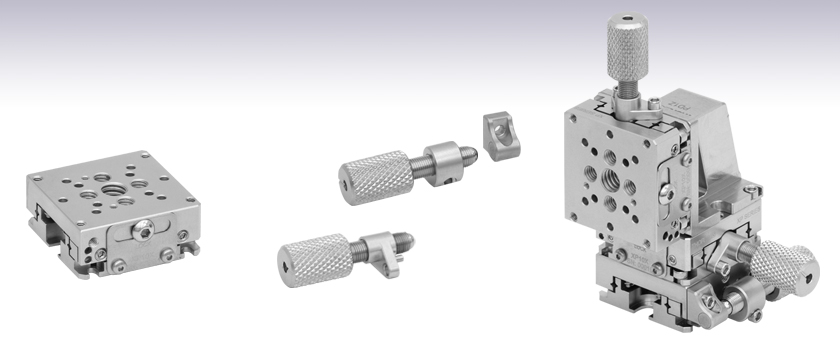

XP10X

10 mm Miniature High Performance Crossed-Roller Bearing Stage, No Actuator

XP10-C1

Side-Mounted Drive Kit for XP10X(/M) Stages

XP10-C2

End-Mounted Drive Kit for XP10X(/M) Stages

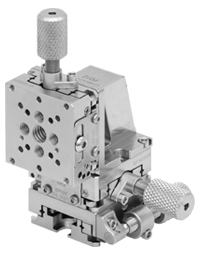

Application Idea

Three XP10X translation stages, one with an XP10-C1 side-mounted actuator and two with XP10-C2 end-mounted actuators, are mounted in an XYZ configuration using the PD1Z right-angle adapter.

Please Wait

| Table 1.1 Specifications | |

|---|---|

| Item # | XP10X(/M) |

| Travel | 10 mm |

| Angular Deviationa | <100 µrad |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) |

| Top Plate Mounting Holes | One 1/4"-20 (M6 x 1.0) Tapped Hole Four 8-32 (M4 x 0.7) Tapped Holes Four 2-56 (M2 x 0.4) Tapped Holes Six Ø0.079" (Ø2.01 mm) Alignment Holes, 0.08" (2.0 mm) Deep Four Ø0.079" (Ø2.01 mm) Alignment Holes, 0.16" (4.1 mm) Deep |

| Bottom Plate Mounting Holes | Three #8 (M4) Counterbored Slots Four #2 (M2) Counterbored Slots Six Ø0.079" (Ø2.01 mm) Alignment Holes, 0.08" (2.0 mm) Deep Two Ø0.079" (Ø2.01 mm) Alignment Holes, 0.16" (4.1 mm) Deep |

| Deck Height | 0.51" (13.0 mm) |

| Bearing Type | Crossed-Roller Bearings |

| Horizontal Load Capacity | 7 lbs (3.2 kg) |

| Vertical Load Capacity | 3 lbs (1.4 kg) |

| Vacuum Compatibility | 10-5 Torr at 25 °C Without Bake Out |

| Actuator Specifications (Sold Separately) | |

| Actuator Item # | XP10-C1 or XP10-C2 |

| Resolution | 500 µm Translation Per Revolution |

| Travel | 10 mm |

| Adjuster Type | Knurled Thumbscrew or 5/64" (2.0 mm) Hex Drive |

| Barrel Size | Ø0.39" (Ø10.0 mm) |

Features

- 10 mm Linear Translation Stages with Separate Interchangeable Actuators

- Crossed-Roller Bearings for High Load Capacity and Low Angular Deviation

- Side- or End-Mounted Manual Knurled Thumbscrew Actuators with Ø0.39" (Ø10.0 mm) Barrel and Integrated 5/64" (2.0 mm) Hex Drive

- Each Stage Individually Tested and Shipped with Test Data Certificate

- Mounts to PD1 Series Bases or Breadboards Using #8 (M4) or #2 (M2) Counterbored Mounting Slots

- Each Part Double Vacuum Bagged and Vacuum Compatible Down to 10-5 Torr at 25 °C Without Bake Out

Thorlabs' XP10X(/M) Miniature Translation Stage provides 10 mm of linear translation with less than 100 µrad of deviation in pitch and yaw over its full range. Featuring a compact 30.0 mm x 30.0 mm footprint (with locking plate and actuator not attached), this stage uses crossed-roller bearings to support precision motion and high load capacities. The top and bottom plates feature mounting holes for attaching the XP10-C1 or XP10-C2 side- or end-mounted manual actuators which are sold separately.

After each stage is manufactured, the pitch and yaw deviation of the stage are tested to ensure that each stage meets the stated specifications over the full translation range of the stage. A summary of the test results is provided on an individualized data sheet that ships with each stage. Sample data sheets can be viewed here.

The mounting surface includes a central 1/4"-20 (M6 x 1.0) tapped hole, an array of four 8-32 (M4 x 0.7) tapped holes with 1/2" (12.5 mm) spacing, and an array of four 2-56 (M2 x 0.4) tapped holes with 1.06" x 0.92" (27.0 mm x 23.4 mm) spacing. A locking plate (engraved with the stage's serial number) can be installed on either side of the stage to guard against accidental movement. The stage can be mounted on the PD1B mounting adapter via two of the 8-32 (M4 x 0.7) counterbored holes on its base. It is compatible with all of our PD1 series stages and mounting accessories, including the PD1Z vertical mounting bracket for XZ or XYZ configurations, as shown in Figure 1.3.

Click to Enlarge

Figure 1.3 These stages can be stacked and mounted in an XYZ configuration using the PD1Z vertical mounting bracket.

Click to Enlarge

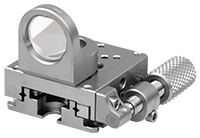

Figure 1.2 The pin holes on the top plate of the stage are designed for compatibility with our Polaris® fixed optic mounts for OEM applications. Shown here is the POLARIS-L05G glue-in lens mount.

These stages are designed so they can be locked in place and the actuator removed, ideal for OEM applications or spatially constrained setups. An array of Ø0.079" (Ø2.01 mm) alignment holes are featured on the top plate of the stage, providing compatibility with our Polaris® fixed optic mounts, as shown in Figure 1.2, as well as many of our Polaris® kinematic mirror mounts.

The XP10-C1 and XP10-C2 side- and end-mounted actuators for the XP10X(/M) stage are sold separately. With 500 µm of travel per revolution, they each feature a knurled thumbscrew for manual rotation. For finer control, the actuators can be rotated using a 5/64" (2.0 mm) hex key (included). The actuators are removable and interchangeable to accommodate the application's requirements.

Note: If mounting the stage using 8-32 (M4 x 0.7) cap screws and the XP10-C2 actuator, only the center and opposite end mounting slots should be used, since a cap screw in the mounting slot adjacent to the actuator mounting point will obstruct the mounting of the actuator.

| Posted Comments: | |

| No Comments Posted |

手動リニアステージ

手動の移動ステージとして、最大移動量が6 mm以下から50 mmまでのステージをご用意しています。ステージの多くはXY軸やXYZ軸などの多軸構成での注文が可能です。ファイバ結合用としては、多軸ステージのページをご覧ください。標準の手動ステージを用いるよりも精密な調整が可能です。直線移動ステージのほかにも、回転ステージ、ピッチ&ヨープラットフォームおよびゴニオメータもご用意しております。また、DCサーボモータ、ステッピングモータ、またはダイレクトドライブ技術を用いた電動移動ステージもご用意しています。

クロスローラーベアリングステージ

こちらの直線移動ステージの移動機構には、精密移動、高耐荷重、小角度偏差といった特性を有するクロスローラーベアリングが用いられています。LNRシリーズステージの本体はスチール製、LX、XRNおよびXRシリーズステージの本体はアルミニウム製です。当社ではクロスローラーベアリングを用いた垂直移動ステージもご用意しております(Table 140E参照)。

| Table 140A Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages | XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |  |  |  |  |  |  |

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) | 2.56" x 2.56" (65.0 mm x 65.0 mm) | 2.00" x 3.35" (50.7 mm x 85.0 mm) | 2.98" x 4.33" (75.7 mm x 110.0 mm) | 2.98" x 5.51" (75.7 mm x 140.0 mm) | 3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations | X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

ボールベアリングステージ

こちらの移動ステージでは、精密移動と長寿命を実現するために、硬化スチール製リニアベアリングが用いられています。様々なアクチュエータが付いた製品や、1軸ステージや予め多軸ステージとして構築された製品をご用意しております。

| Table 140B Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |  |  |  |  |

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) | 0.76" x 0.81" (19.3 mm x 20.6 mm) | 2.40" x 2.41" (61.0 mm x 61.2 mm) | 3.00" x 4.00" (76.2 mm x 101.6 mm) | 3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

アリ溝式ステージ

これらの小型ステージの移動機構にはアリ溝と送りネジが組み込まれています。一般的な移動制御用に適したステージです。

| Table 140C Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) | DTS Series 2" Stage |

| Click Photo to Enlarge |  |  |  |

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

フレクシャーステージ

移動ステージNanoflex™には摩擦の無いフレクシャー機構が用いられており、ベアリングを用いた同様のステージと比較して位置決め性能と分解能が向上しています。ステージの移動は、取付けプラットフォームに取り付けられた連結部の弾性変形(たわみ)によって実現されています。多くのモデルには、微細な位置調整用にピエゾアクチュエータも付属します。

| Table 140D Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |  |  |  |

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator | Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

垂直移動ステージ

当社では精密移動用のクロスローラーベアリングを用いた垂直移動ステージや、高荷重用の長距離垂直移動ステージもご用意しております。

| Table 140E Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |  |  |  |  |  |

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) | 2.98" x 2.98" (75.7 mm x 75.7 mm) | 2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

- 10 mm Single-Axis Translation

- 1.18" x 1.18" (30.0 mm x 30.0 mm) Platform Size

- 0.51" (13.0 mm) Deck Height

- Vacuum Compatible Down to 10-5 Torr at 25 °C Without Bake Out

The XP10X(/M) stage allows for 10 mm of travel along a linear axis with <100 µrad of angular deviation. Actuators for moving the stage are not included and are sold separately below. Four 2-56 (M2 x 0.4) mounting holes on the top plate and #2 (M2) counterbored slots on the base allow these stages to be stacked orthogonally for an XY configuration. A PD1Z vertical bracket can be mounted on the XY configuration for three-dimensional translation as shown in Figure 1.3.

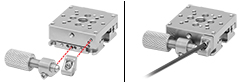

Click to Enlarge

Figure G2.1 The XP10-C1 actuator can be mounted to the side of the XP10X(/M) stage to drive it without significantly increasing its footprint.

Click to Enlarge

Figure G2.2 The XP10-C2 actuator can be mounted to the end of the XP10X(/M) stage to drive it without increasing its width.

- Compatible with XP10X(/M) Series Stages

- Kits to Switch Between Side- and End-Mounted Micrometer Designs

- XP10-C1: Side-Mounted

- XP10-C2: End-Mounted

The XP10-C1 and XP10-C2 drive kits are actuators for the XP10X(/M) 10 mm translation stage. Each actuator includes two 2-56 socket head cap screws and features integrated alignment pins that mate with the XP10X(/M) stage for straightforward and repeatable mounting. The XP10-C1 drive kit mounts to the side of the stage while the XP10-C2 drive kit mounts to the end of the stage. The mounting locations and procedure for attaching each drive kit are shown in Figure G2.1 and G2.2. The thumbscrew knobs can also be removed from each actuator using the included 5/64" (2.0 mm) hex key on the end-located screw. With the knob removed, two Ø0.07" (Ø1.8 mm) through holes on the adjuster can be used to rotate the adjuster screw, or adapted for custom use.

Products Home

Products Home

ズーム

ズーム

Linear Stage: 10 mm

Linear Stage: 10 mm