Fixed Periscope for OEM Applications

- Fixed Periscope for Mounting Ø1" Mirrors

- Matching Bottom Optical Axis Height for OEM Applications

- Spacers and Shims for Adjusting Upper Optical Axis Height

- Baseplates Available for Mounting Flexibility

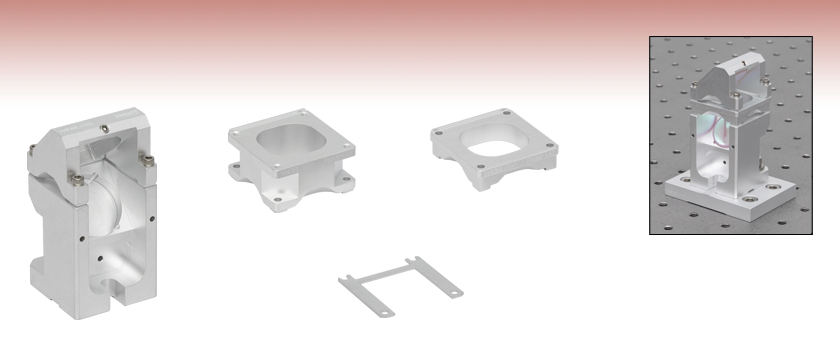

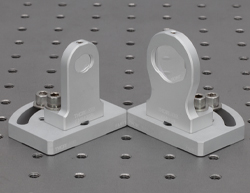

FMMP1

Fixed Ø1” Periscope for OEM Applications

FMMP1A3

20 mm Spacer for Fixed Periscope

FMMP1A2

10 mm Spacer for Fixed Periscope

FMMP1A1

1 mm Shim for Fixed Periscope

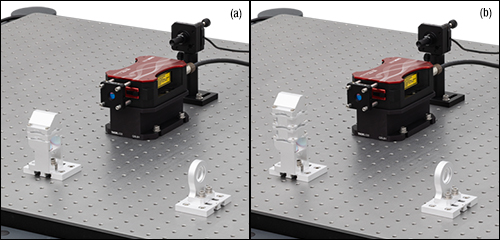

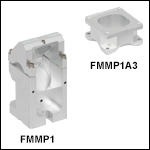

Application Idea

An FMMP1 OEM periscope with an FMMP1A2 spacer is mounted on an FMB2 baseplate for alignment flexibility.

Please Wait

Click to Enlarge

Figure 1.1 The FMMP1 periscope and an FMB2 baseplate can be used to test various pump lasers in conjunction with an optical setup. Lasers from different manufacturers will have different beam heights and beam location relative to their mounting holes. An assortment of shims and spacers will accommodate the different beam heights and the translation baseplate can accommodate different locations of the beam relative to the table hole pattern. Here, the periscope is aligned with the QSL103A laser using an FMMP1A2 spacer (a) or aligned with the PL201 laser using two FMMP1A3 spacers (b) before bringing the beam down to the height of the FLM1 fixed lens mount.

Features

- Fixed Periscope for Ø1" Optics

- Suitable for Vacuum Applications When Nylon-Tipped Setscrew Removed

- Optic Mounting Options:

- Nylon-Tipped Setscrew Secures Optic in Mounts

- Mounting Plane and Four Glue Ports per Optic for Glue-In Mounting

- Common Bottom Optical Axis Height of 1.50" (38.1 mm)

- Mounting Holes for Use with 1/4" (M6) Screws

- Can be Mounted Directly to Breadboard or with Translation or Rotation Baseplates

Contact Us for Your Custom and OEM Projects

Leon Chen, Gary Zimberg,

Angelika Karlowatz

Thorlabs Global Sales Directors

We look forward to hearing from you!

Thorlabs' Fixed Periscope was designed to meet the needs of OEM customers. To that end, we are equipped to manufacture these mounts in high volumes and with timed delivery. Additionally, we can design and manufacture modified versions of these mounts for mounting additional optic types, sizes, and shapes. For example, we have produced similar fixed mounts for square mirrors, diffraction gratings, different optic sizes, or different beam heights.

If you have a custom or OEM project, we invite you to contact us to discuss how our engineering expertise and manufacturing capabilities can help you achieve your goals.

The FMMP1(/M) Fixed Periscope for OEM Applications is designed to lower or raise a beam to or from the unified 1.50" (38.1 mm) optical axis height of our fixed lens mounts and fixed mirror mounts, supporting a seamless transition from benchtop R&D to high-volume OEM laser system production. This periscope accepts two Ø1" mirrors (not included) that can be secured in the top or bottom 45° mirror mounts by a nylon-tipped locking setscrew, which can be fastened using a 5/64" (2.0 mm) balldriver or hex key. Eight optic glue ports are included for more permanent mounting or applications in vacuum environments. The periscope, as well as the spacers and shims sold below, are fabricated from acid-etched 6061-T6 aluminum and double vacuum-bagged, making them suitable for cleanroom and vacuum chamber environments; vacuum specifications are provided in Table 1.2.

The bottom mirror mount on the FMMP1(/M) periscope is centered at a height of 1.50" (38.1 mm) while the top mirror mount is centered at 2.36" (60.0 mm). To flexibly incorporate the FMMP1(/M) periscope into systems with different beam heights, the height of the top mount can be increased in steps of 1 mm, 10 mm, or 20 mm by inserting the FMMP1A1, FMMPA2, or FMMPA3(/M) spacers sold below. The fixed optic height of the bottom mount and fixed mechanical footprint allow for direct transfer of mounts into the proven system, with a cavity-ready form factor supporting direct mounting into custom laser system substructures. This overall architecture enables OEM designers to rapidly develop and iterate optical systems on standard breadboards, then deploy those exact assemblies in production environments with no change in alignment geometry, reducing validation requirements and increasing long-term system reliability.

Baseplates for OEM Fixed Optical Mounts

Baseplates are available separately, including manual translation baseplates, which provide up to 1.25" (31.8 mm) of linear mount travel, and rotation baseplates, which offer up to 90° of rotational adjustment. Using these baseplates keeps the bottom mirror height at the same level as other OEM mounts that also use these baseplates. This compatibility provides great interchangeability with our other OEM mounts. For example, if a fixed lens mount was mounted in a beam path, it could be directly replaced with a periscope to raise the beam height. Two through holes on the base, spaced 0.75" apart, are designed to accept 1/4" (M6) screws for mounting to these bases, including one tight-fit clearance hole for use with a shoulder screw of the same size to aid in positioning. Additionally, a mounting slot and a centered hole are spaced 1.00" (25.0 mm) apart for mounting directly to a standard breadboard or optical table. There is also a center-aligned 1/4"-20 (M6 x 1.0) tapped hole that can be used with a dowel pin adapter to rotate the periscope continuously; in this case, the periscope can be secured at any angle using table clamps.

| Table 1.2 Vacuum Specifications | |

|---|---|

| Vacuum Compatibility as Packageda,b | >10-6 Torr |

| Materials | 6061-T6 Aluminum |

| Preparation and Packaging | Chemically Cleaned and Double Vacuum-Bagged |

| Posted Comments: | |

| No Comments Posted |

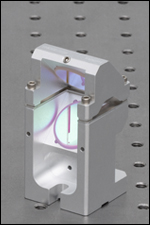

Click to Enlarge

Figure G1.2 The FMMP1A3 shim is mounted between the top and bottom halves of the FMMP1 periscope to raise the top optical axis by 20 mm.

Click to Enlarge

Figure G1.2 The FMMP1A2 shim is mounted between the top and bottom halves of the FMMP1 periscope to raise the top optical axis by 10 mm.

Click to Enlarge

Figure G1.1 The FMMP1A1 shim is mounted between the top and bottom halves of the FMMP1 periscope to raise the top optical axis by 1 mm.

- 1.50" (38.1 mm) Bottom Optical Axis Height for OEM Applications

- Spacers and Shims Available for Raising Top Optical Axis from 60.0 mm by 1, 10, or 20 mm

- Accepts Ø1" (Ø25.4 mm) Optics

- Mounting Holes on Base for 1/4" (M6) Screws

- Suitable for Vacuum Applications if Optics are Glued In

To increase the height of the top axis of the FMMP1(/M) persiscope by 1 mm, an FMMP1A1 shim can be inserted into the periscope. First remove the four top-located 4-40 (M3 x 0.5) cap screws using a 3/32" (2.5 mm) balldriver or hex key. The top portion of the persicope can then be removed and the shim can be placed on top of the bottom portion, lining up the clearance holes, before replacing the top portion and re-inserting the previously removed screws.

To insert an FMMP1A2 10 mm spacer into the periscope, first remove the top portion as described above, then line up the clearance holes on the spacer with the tapped holes on the bottom portion. Then, line up the top portion of the periscope with the back alignment edge on the spacer and insert the 1" long #4 (M3) cap screws that are included with the 10 mm spacer to connect the three pieces. This alignment edge provides an accurate and repeatable 0°, 90°, 180°, or 270° separation between input and output beams. This spacer is designed with extra material on its bottom side so that up to 6.5 mm of its height can be milled down without disturbing the alignment edge if an intermediate-sized spacer is needed. If the height of the spacer is reduced by more than 1.5 mm, shorter screws (3/4" length, not included) are required for incorporating into the periscope.

To insert an FMMP1A3 20 mm spacer into the periscope, first remove the top portion as described above, then line up the clearance holes on the spacer with the tapped holes on the bottom portion. Insert the four 3/8" long button head cap screws that are included with the 20 mm spacer through the clearance holes in the bottom of the spacer and into the bottom portion of the periscope. Then, line up the top portion of the periscope with the back alignment edge on the spacer and reinsert the four 4-40 (M3 x 0.5) cap screws to connect the top portion to the spacer. This alignment edge provides an accurate and repeatable 0°, 90°, 180°, or 270° separation between input and output beams.

The periscope halves can also be separated to direct the beam vertically between stacked optical plates. The top section can be mounted on one FMMP1A2 10 mm spacer and one FMMP1A3(/M) 20 mm spacer to bring it to within 1 mm of the standard 1.50" (38.1 mm) beam height. This configuration requires a different mounting pattern, using four 4-40 (M3 x0.5) tapped holes with 1.26" square spacing.

- Attach OEM Fixed Optical Mounts via 1/4"-20 (M6 x 1.0) Square Nut

- Mount on Breadboard or Optical Table via Clearance Hole for 1/4" (M6) Cap Screws

- Translation Slot Provides Up to 1.25" (31.8 mm) Linear Translation

This baseplate provides compatibility between our OEM fixed optic mounts and standard breadboards or optical tables. Each baseplate includes four counterbored mounting holes for 1/4" (M6) cap screws to secure it to the optical table. Optic mounts are attached using two 1/4"-20 (M6 x 1.0) square nuts inserted into the translation clearance slots on the baseplate. This configuration allows the mounts to be translated by up to 1.25" (31.8 mm) while the baseplate remains stationary, as shown in Figure G2.1.

The FMB2(/M) translation baseplate is compatible with the fixed periscope sold on this page as well as our fixed lens mounts and fixed mirror mounts for OEM applications that are designed for Ø1/2" (Ø12.7 mm) and Ø1" (Ø25.4 mm) optics.

Click to Enlarge

Figure 788A ダイクロイックミラーを装着したリアローディング固定式ミラーマウントをベースプレートFMB1(/M)に取り付けた様子

- M6 x 1.0タップ穴で固定式光学マウントを取り付け

- 付属の位置決めピン用アダプタが回転軸となり回転可能

- ブレッドボードや光学テーブルに取り付ける際にはM6キャップスクリュ用スロットを使用

- 貫通スロットにより最大90°の回転が可能

回転ベースプレートFMB1/Mを使用して、製品組み込み用途(OEM用途)向け固定式光学マウントを標準ブレッドボードや光学テーブルに接続できます。 ベースプレートの4つのM6 x 1.0タップ穴はすべての固定式光学マウントの設置用です。付属の位置決めピン用アダプタは、中央のM6 x 1.0タップ穴にネジ止めされており、ブレッドボードや光学テーブルにある穴の1つに設置したときにベースプレートを回転させるための回転軸となります。湾曲した貫通スロットにより、ベースプレートをブレッドボードや光学テーブルに取り付けた状態で(取付用のキャップスクリュを取り外さなくても)最大90°の回転が可能です。

Products Home

Products Home

ズーム

ズーム

Fixed Periscope for OEM Applications

Fixed Periscope for OEM Applications