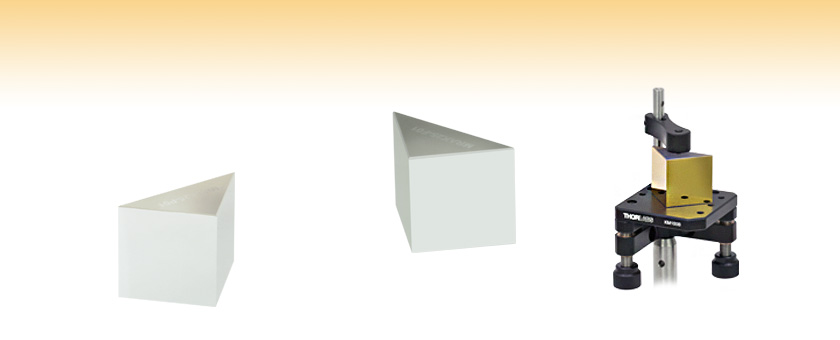

ナイフエッジ直角プリズムミラー

- Precision Cut Prisms Feature Bevel-Free 90° Angle

- Silver, Gold, and Aluminum Coatings Available

- 25 mm x 25 mm Faces

MRAK25-P01

MRAK25-F01

Application Idea

MRAK25-M01 Mounted

on a KM100B Kinematic

Platform Mount

Please Wait

Figure 1.2 プリズムのサイズは直角を挟む辺の長さLで定義されています。製品の全寸法については「仕様」タブをご覧ください。

Click to Enlarge

Figure 1.1 この図は、ナイフエッジ直角プリズムミラーを使用して、どのように2本のビームを同一直線に揃えることができるかを示しています。

特長

- 直角を挟む2面がミラーコーティングされた直角プリズム

- 2つのコーティング面で構成される「ナイフエッジ」によるビームの合流または分割

- 反射面:25 mm x 25 mm

ナイフエッジ直角プリズムミラーは、直角を挟む2面が反射コーティングされており、有効開口が90°の2つのコーティング面に渡っています。プリズムはN-BK7製で、反射面の大きさは25 mm x 25 mmです。プリズムミラーのコーティングは、UV域強化アルミニウム、保護膜付きアルミニウム、保護膜付き金、または保護膜付き銀のいずれかからお選びいただけます。それぞれのコーティングの反射率の詳細は、「仕様」タブおよび「グラフ」タブをご覧ください。

2つのコーティング面は高精度に直角になっているため、反対方向に伝播する2本の入射ビームは共に直角に反射され、出射ビームはコリニアになります(Figure 1.1参照)。また、1本の入射ビームをナイフエッジで分割することもできます。このプリズムは、セットアップの配置などの関係でビームスプリッターキューブを使用できない場合に有用です。このプリズムを使用してビームを分割した場合、ある程度の回折や散乱が発生します。

これらのプリズムは、エッジ部分までコーティングされています。コーティングされたエッジはとても壊れやすく、簡単に欠損する恐れがありますので、プリズムを取り扱うときにはご注意ください。

プリズムの斜面は研磨されていますが、コーティング工程で使用された接着層があるため、レトロリフレクタとして使用することは想定していません。そのため、プリズムの研磨された斜面については仕様化されていません。レトロリフレクタ用としては、コーティング無しの直角プリズムPS911K、あるいは当社のマウント付きやマウント無しのレトロリフレクタをお勧めします。当社では斜面をコーティングした直角プリズムミラーもご用意しております。

| Right Angle Prism Mirror Selection Guide |

|---|

| Hypotenuse Coated |

| Metallic Coatings (250 nm - 20 µm) |

| Dielectric Coatings (400 nm - 1100 nm) |

| Laser Line (532 nm and 1064 nm) |

| Leg Coated |

| Knife-Edge, Metallic and Dielectric Coatings (250 nm - 20 µm) |

| Dielectric Coating (750 nm - 1100 nm) |

取扱いについて

銀コーティングのミラーは、環境条件や不適切な取扱いによって損傷しやすいため、特に注意が必要です。指紋の付着、研磨性のある面との接触、高湿・高温の環境などにより、保護膜の効果が損なわれ、銀コーティングの酸化や劣化が起きやすくなります。銀ミラーを取り扱う際は、光学素子の標準的な取扱い方法に従ってください。 光学素子の表面に指の油分などが付着するのを防ぐために、Latex製手袋などの着用をお勧めします。こうした対策を講じていても、ミラー面やエッジには触れないようにご注意ください。銀ミラーは、できるだけ低湿度の室温で使用し、保管してください。ミラーなどの光学素子のクリーニング方法については、「光学素子の取扱いについてのチュートリアル」をご参照ください。

| Item # | MRAK25-F01 | MRAK25-G01 | MRAK25-P01 | MRAK25-M01 | |

|---|---|---|---|---|---|

| Coating (On Legs) | UV Enhanced Aluminum | Protected Aluminum | Protected Silver | Protected Gold | |

| Reflectancea | Ravg > 90% (250 -450 nm) | Ravg > 90% (450 - 2000 nm) Ravg > 95% (2 - 20 µm) | Ravg > 97% (450 - 2000 nm) Ravg > 95% (2 - 20 µm) | Ravg > 96% (800 nm - 20 µm) | |

| Substrate Material | N-BK7 | ||||

| Lb | 25.0 mm | ||||

| Xb | 35.4 mm | ||||

| Clear Aperture (Coated Surfaces) | Entire Face Length and Width, Excluding a 1.25 mm Border Along All Beveled Edges | ||||

| Clear Aperture (Hypotenuse) | 90% of Face Length and Width | ||||

| Surface Flatness (All Surfaces) | λ/8 @ 632.8 nm Over the Clear Aperture (Peak to Valley) | ||||

| Surface Quality | 20-10 Scratch-Dig | ||||

Figure 2.1 直角プリズムの寸法

Figure 2.1 直角プリズムの寸法 Figure 2.2 直角プリズムの図

Figure 2.2 直角プリズムの図下記は、特に明記のない限り、すべて無偏光の光でのデータです。グラフの網掛けされている部分は、この光学素子の推奨波長範囲を示しています。この帯域の外側(特に反射率のグラフに変動や傾斜がみられる範囲)の反射率は、ロット毎にバラつきがある可能性があります。

UV域強化アルミニウムコーティング (250~450 nm)

保護膜付きアルミニウムコーティング (450 nm~20 µm)

保護膜付き銀コーティング(450 nm~20 µm)

保護膜付き金コーティング(800 nm~20 µm)

| Posted Comments: | |

Yaogeng Ding

(posted 2025-05-08 14:08:09.293) Do you have smaller Knife-Edge Right-Angle Prism Prot. Silver Mirror, 450 nm-20 µm, L = 10 mm? jpoling

(posted 2025-05-09 07:25:13.0) Thank you for contacting Thorlabs. Requests for customizations can be made by emailing us at techsales@thorlabs.com. I have reached out to you directly to discuss this request in more detail. Peter Domenicali

(posted 2025-02-24 08:42:31.04) Several previous customers have inquired about the sharpness of the knife edge. The most recent answer was that you expect it to be less than 100 um. Short of us buying one and examining it under a microscope, can you please advise whether the maximum width of the edge break might be less than 20 um? That is our present requirement for such a component, so we need to know whether this part will meet our needs. Bram Verreussel

(posted 2024-10-15 08:25:10.05) What coating is used for the MRAK25 prisms? Specifically the P01 and M01 prisms. The coatings seem to be degraded after 8 years but it's hard to tell what's happening without knowing what the coating is made of. jpolaris

(posted 2024-10-18 07:47:28.0) Thank you for contacting Thorlabs. The MRAK25-P01 and MRAK25-M01 knife-edge right-angle prism mirrors are coated with our 'protected silver' and 'protected gold' coatings, respectively. A page detailing these two coatings, as well as our other metallic and dielectric coatings, can be found at the following link. "Protected" in these two cases refers to the fact that these coatings have an SiO2 overcoat, which helps prevent damage from scratching and smudging, and delays corrosion/ oxidization. I have reached out to you directly to discuss the environmental conditions your prisms were used and stored in. Aside from environmental conditions, damage can occur optically. I have included laser-induced damage thresholds for the -P01 and -M01 coatings in my email to you. https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=5840&tabname=HR_Coating Will Christopherson

(posted 2024-03-26 16:57:20.8) I would also like to understand current measurements on the knife edge sharpness. Specifically my use would be to position the edge to split imaged spots separated by ~100 um. Thanks! jdelia

(posted 2024-04-18 08:49:41.0) Thank you for contacting Thorlabs. We do not explicitly characterize the sharpness of the edge, but based on our measurements and testing procedures, we would expect the edge to be sharper than 100um. user

(posted 2023-11-06 17:11:39.37) What is the dead zone "thickness" of the knife edge ? cdolbashian

(posted 2023-11-15 09:46:55.0) Thank you for reaching out to us with this inquiry. On the product page we state the following "These prisms feature a coating that extends to the edge of the optic", indicating that there is no "dead zone" on the optic. I have reached out to you directly to discuss this, in the case where I am misunderstanding your inquiry. RAMPRAKASH ANANTHAPADMANABAN

(posted 2023-09-28 02:21:57.04) Hi,

I have two laser beams that are 10 mm apart. Can I use MRAK25-P01 to redirect it perpendicular to the incoming direction? jpolaris

(posted 2023-09-28 05:13:53.0) Thank you for contacting Thorlabs. Yes, our Knife-Edge Right-Angle Prism Mirrors, such as MRAK25-P01, can be used to redirect parallel beams into opposite perpendicular directions. The coated faces of MRAK25-P01 have side lengths of 25 mm, so there would be no issues from your 10 mm beam spacing. Yuqin Yan

(posted 2023-03-15 19:39:07.857) MRAK25-E03 jdelia

(posted 2023-03-23 09:34:34.0) Thank you for contacting Thorlabs. I have reached out to you directly to clarify what your question regarding MRAK25-E03, and also discuss some alternative options to this obsolete part. Daniel Dickinson

(posted 2021-04-26 08:54:08.217) I noted from previous comments that you are able to offer these prisms with dielectric coatings. Can you please reach out to me with a quote for the E02 coating?

I was also curious if it's possible to make these prisms with a higher surface flatness, similar to your BB1 mirrors (lambda/10). YLohia

(posted 2021-04-26 01:55:37.0) Thank you for contacting Thorlabs. Custom optics can be requested by emailing techsupport@thorlabs.com. We will reach out to you to discuss the possibility of offering this customization. Lorenz Sykora

(posted 2020-07-23 12:28:32.3) Is ist possible to get it also with unprotected gold. We are working in the midinfrared region and the absorption of the protected gold for 45° is way to much. 45° would be the standard angle for this optical component. YLohia

(posted 2020-07-23 02:39:03.0) Thank you for contacting Thorlabs. Custom optics can be requested by emailing techsupport@thorlabs.com. We will reach out to you to discuss the possibility of offering this customization. Marshall Scott

(posted 2019-10-21 14:37:34.193) rstahl (posted 2018-05-01 14:47:00.51)

How sharp is the knife edge? How small a beam diameter could I split with this part?

YLohia (posted 2018-05-02 10:31:35.0)

Hello, unfortunately, we do not specify an exact thickness of the knife edge on these prisms; we design the thickness of the edge as thin as our manufacturing abilities allow and is suited for general beamsplitting and beam combining applications.

:( YLohia

(posted 2019-11-05 03:15:05.0) We specify no chamfer on this surface to ensure working distance is available as close to the edge as possible. We are currently working on defining a specification as to how sharp that edge actually is. I will reach out to you via e-mail to discuss this further. lebouquj

(posted 2018-06-07 16:32:10.937) Hello, Could you offer MRAK20-M01, that is with 20mm legs instead of 25mm ? Thanks, Jean-Baptiste nbayconich

(posted 2018-06-12 10:15:57.0) Thank you for contacting Thorlabs. We can look into providing this custom for you. I will reach out to you directly with more information.

For any custom requests please contact techsupport@thorlabs.com directly. simon.neves

(posted 2018-05-03 17:13:22.78) Dear Sir/Madam,

Do you provide a knife edge with dielectric coatic for 1550 nm wavelength ?

Thank you for your help

Simon Neves YLohia

(posted 2018-05-04 10:02:31.0) Dear Simon, thank you for contacting Thorlabs. We do have the ability to provide these knife-edge right-angle prisms with our selection of dielectric coatings as specials. We will contact you directly for more details. rstahl

(posted 2018-05-01 14:47:00.51) How sharp is the knife edge? How small a beam diameter could I split with this part? YLohia

(posted 2018-05-02 10:31:35.0) Hello, unfortunately, we do not specify an exact thickness of the knife edge on these prisms; we design the thickness of the edge as thin as our manufacturing abilities allow and is suited for general beamsplitting and beam combining applications. pierrick.cheiney

(posted 2018-04-17 15:59:01.933) Dear Sir/Madam,

Could you provide knife-edge prism mirror in smaller size such as 5 or 10 mm width?

Best regards,

Pierrick Cheiney YLohia

(posted 2018-04-17 11:17:46.0) Hello Pierrick, thank you for contacting Thorlabs. We will reach out to you directly to discuss the possibility of offering this. yitzhak.malka

(posted 2018-01-31 08:59:18.217) Can you please indicate the 90degree angle accuracy? nbayconich

(posted 2018-02-07 04:19:12.0) Thank you for contacting Thorlabs. The tolerance to the 90 degree angle is ±3 arcminutes. cmullark

(posted 2018-01-18 05:27:01.987) I have a question:

What is the thickness of the knife-edge? If I place the prism in the focal plane of a beam to split it than as I focus tighter and tighter there will be more scattering/loss determined primarily by the knife edge thickness. Would it be different between the dielectric coating and the protected silver?

Thanks for any help you can provide in this matter. nbayconich

(posted 2018-03-30 04:25:50.0) Thank you for contacting Thorlabs. We do not specify an exact thickness for either coating type of these knife edge prisms, we design the thickness of the edge as thin as our manufacturing abilities allow. |

Products Home

Products Home

ナイフエッジ直角プリズムミラー

ナイフエッジ直角プリズムミラー