Mini-Series Slotted Bases

- Compatible with Mini-Series Posts

- Available with Imperial or Metric Footprint

- Bottom Relief Cuts Ensure Stable Mounting

MBA1S

Mini-Series Mounting Base,

0.39" x 1.00" x 0.25"

MBA1B

Mini-Series Mounting Base,

0.39" x 1.18" x 0.25"

MBA2

Mini-Series Mounting Base,

1.18" x 1.18" x 0.25"

Application Image

Mini-Series Assembly Mounted on a MBY6 Breadboard

Please Wait

Features

- Compatible with Mini-Series Imperial and Metric Breadboards and Posts

- Attach to Posts via Bottom-Located #4 (M3) Counterbored Mounting Hole(s)

- Mount on Breadboard or Optical Table via Clearance Slot(s) for #4 (M3) Cap Screws

- Fabricated from Black Anodized Aluminum with Bottom Relief Cuts for Stable Mounting

Thorlabs offers a variety of Mini-Series anodized aluminum bases to mount Mini-Series components in a compact assembly. For close positioning of components, our MBA1S(/M) base features the smallest footprint of 0.39" x 1.00" x 0.25" (9.5 mm x 25.0 mm x 6.0 mm). For increased stability while maintaining a small footprint of 0.39" x 1.18" x 0.25" (9.5 mm x 29.5 mm x 6.0 mm), the two-slotted MBA1B(/M) is a good option. For the greatest stability, consider our MBA2(/M) base, which offers the largest contact area of 1.18" x 1.18" x 0.25" (29.5 mm x 29.5 mm x 6.0 mm), and features two straight slots.

Please note that a 0.25" long, 4-40 (6 mm long, M3) cap screw (Item #s SH4S050 and SH3M12, respectively) is recommended for attaching Mini-Series posts to these mounting bases.

| Image (Click to Enlarge) |

Description |

|---|---|

MBE1 |

Base Adapter for Mini-Series Posts The MBE1 Pedestal Base Adapter features a #4 (M3) counterbore for compatibility with the bottom of our Mini-Series posts to convert them into pedestal-style mounts. Made from solid 303 stainless steel with a 0.56" (14.2 mm) outer diameter, this adapter allows these posts to be used with our MSC1, MSC3, and MSC2 clamping forks. |

BE1 |

Base Adapter for Ø1/2" Post Holders and Ø1" Posts The BE1 Pedestal Base Adapter features a 1/4"-20 (M6)-threaded stud which fits into the bottom of our standard Ø1/2" post holders or Ø1" post extensions to convert them into pedestal-style mounts. Made from solid 303 stainless steel with a 1.25" (31.8 mm) outer diameter, this adapter allows these posts to be used with our CF125 and CF175 clamping forks. |

RS05PC |

Ø1" Ceramic Pedestal Pillar Post The RS05PC Ceramic Pedestal Post is designed to provide high levels of thermal and electrical isolation. It is ideal for mounting components that may be sensitive to heat or sources of electrical noise. This adapter is compatible with our CF125 and CF175 clamping forks. |

CF125 |

Small Clamping Fork The CF125 Clamping Fork was designed with positional flexibility in mind. This clamping fork is directly compatible with our Pedestal Style Post Holders and RSP-Series Ø1" Pedestal Pillar Posts. The solid steel construction, complete with carefully placed relief cuts and landing pads, provides exceptional clamping stability. The counterbored slot is 1.25" (32 mm) in length, is designed to accept a 1/4"-20 (M6) cap screw and washer, and allows the clamp to swivel about the pedestal base in order to align with the most convenient mounting holes. |

CF175 |

Large Clamping Fork The CF175 Clamping Fork was designed with positional flexibility in mind. This clamping fork is directly compatible with our Pedestal Style Post Holders and RSP-Series Ø1" Pedestal Pillar Posts. The solid steel construction, complete with carefully placed relief cuts and landing pads, provides exceptional clamping stability. The counterbored slot is 1.75" (44.4 mm) in length, is designed to accept a 1/4"-20 (M6) cap screw and washer, and allows the clamp to swivel about the pedestal base in order to align with the most convenient mounting holes. |

POLARIS-CA1 |

Polaris™ Non-Bridging Clamping Arm The Polaris Clamping Arm is the ideal solution for stably mounting any Ø1" post. Each clamping arm, which is constructed from heat-treated, stress-relieved 303 stainless steel, provides extremely high holding forces with minimal torquing of the mounting screws. The side-located clamping mechanism is actuated using a 1/4"-20 cap screw. Because the side-located clamp and mounting slot are tightened separately, the user can set the position of the fork and adjust the rotational alignment independently. The clamping arm has a compact 3.33" x 1.60" (84.5 mm x 40.6 mm) footprint for tight laser cavity setups, with a thickness of 0.60" (15.2 mm) for increased stability. A 1.30" (33.0 mm) long clearance slot allows for a variety of mounting solutions using a 1/4"-20 or M6 cap screw and washer. This clamping arm is also avaiable with a metric cap screw (POLARIS-CA1/M). |

PB4 |

Base Adapter for Ø1" Post Holders and Ø1.5" Posts The PB4 pedestal base adapter features a 1/4"-20 (M6)-threaded stud which fits into the bottom of our Ø1.5" posts to convert them into pedestal-style mounts. Made from solid 303 stainless steel with a 1.85" (47.0 mm) outer diameter, this adapter allows these posts to be used with our PF85B, PF125B, or PF175 clamping forks. |

PB4R |

Magnetic Base Adapter for Ø1" Post Holders and Ø1.5" Posts The PB4R pedestal base adapter features a 1/4"-20 (M6)-threaded stud which fits into the bottom of our Ø1.5" posts to convert them into pedestal-style mounts. Made from solid 303 stainless steel with a 1.85" (47.0 mm) outer diameter, this adapter allows these posts to be used with our PF85B, PF125B, or PF175 clamping fork. There are four high strength magnets in the base that are sufficiently strong to securely hold the base in place on an optical table. |

PF85B |

Compact P-Series Clamping Fork The PF85B is specifically designed to secure our Ø1" Post Holders or our PB4 pedestal base adapters. It has a 0.85" (21.6 mm) long counterbored slot that is designed to accept a 1/4"-20 (M6) cap screw and washer. The clamp can swivel about the pedestal base in order to align with the most convenient mounting holes. |

PF125B |

Small P-Series Clamping Fork The PF125B is specifically designed to secure our Ø1" Post Holders or our PB4 pedestal base adapters. It has a 1.25" (31.8 mm) long counterbored slot that is designed to accept a 1/4"-20 (M6) cap screw and washer. The clamp can swivel about the pedestal base in order to align with the most convenient mounting holes. |

PF175B |

Large P-Series Clamping Fork The PF175B is specifically designed to secure our Ø1" Post Holders or our PB4 pedestal base adapters. It has a 2.12" (53.8 mm) long counterbored slot that is designed to accept a 1/4"-20 (M6) cap screw and washer. The clamp can swivel about the pedestal base in order to align with the most convenient mounting holes. |

PB1 |

Mounting Post Base for Ø1.5" Posts This standard Ø2.48" post base bolts directly onto P-Series posts and adds 0.40" to the height of the post. To mount directly onto an optical bench, four 1/4 (M6) counterbored holes on 2" (50 mm) centers are provided. |

PB2 |

Slotted Mounting Post Base for Ø1.5" Posts This universal Ø2.40" post base allows random placement of a P-Series post on an optical bench. The PB2 attaches to the P-Series posts using the 1/4"-20 (M6) center-tapped hole and adds 0.50" to the height of the post. |

KB1X1 |

1" x 1" Kinematic Base This kinematic base consists of two plates: a top mounting plate and a bottom base plate. The two plates measure 1" (25 mm) to a side and are magnetically coupled using two pairs of high strength magnets. The top plate can be removed and replaced, automatically repositioning to an exact location with the repeatability of one microradian. The bottom plate can be fastened using a center-located #8 (M4) counterbore. Both the top (Item# KBT1X1) and bottom (Item# KBB1X1) plates can be purchased separately. |

KB3X3 |

3" x 3" Kinematic Base This kinematic base consists of two plates: a top mounting plate and a bottom base plate. The two plates measure 3" (75 mm) to a side and are magnetically coupled using two pairs of high strength magnets. The bottom plate can be fastened to an optical bench using two 1/4"-20 (M6) clearance slots. These mounting slots can be accessed with the top plate in place. Both the top (Item# KBT3X3) and bottom (Item# KBB3X3) plates can be purchased separately. |

KBM1 |

Lockable Kinematic Breaboard (3.94" x 3.94") This kinematic base consists of two plates: a top mounting plate and a bottom base plate. The two plates measure 3.94" (100 mm) to a side and are magnetically coupled using two pairs of high strength magnets. With a ball and V-groove design, the top plate can be removed and replaced with a lateral repeatability of 30 µm. The high repeatability of the unit allows minimal readjustment of the setup for applications where frequent removal and insertion of components is needed. The top plate has an array of 39 1/4"-20 (M6) tapped holes [0.46" (11.8 mm) deep] spaced 0.5" (12.5 mm) apart and provides the same mounting functionality as an optical breadboard. The bottom plate has two 2.00" (50.0 mm) long counterbored slots for 1/4"-20 (M6) cap screws for mounting to an optical table. |

RB2 |

Adjustable Height Post Base The RB2 has a 0.90" (23 mm) deep base, which allows for maximum height adjustment of the RS Series of pillar posts. The locking screw is located on the top surface of the base, allowing for convenient vertical access. |

MB175 |

Magnetic Base For use with our standard Ø1/2" stainless steel post or our Ø1" post holders, this heavy-duty magnetic base has a switchable magnet for quick positioning of optical components. It provides 175 pounds of holding force. The two bottom mounting surfaces have been precision ground for optical bench applications. |

IB3 |

Instrument Base The IB3 precision-machined aluminum instrument base provides flat, stable mounting and is useful for maneuvering items such as a post-mounted power meter head into and out of the beam path. |

PMB3 |

Permanent Magnetic Base The PMB3 combines the convenience of our IB3 Base (above) with the benefit of a powerful magnet. The magnet is sufficiently strong to hold the base in place securely without needing to clamp it to an optical table. These bases are ideal for semi-permanent placement of an instrument or optical head. |

SB1 |

Switchable Kinematic Base This compact kinematic base is designed to allow easy removal and exact repositioning of the top plate. An On/Off switch controls the magnetic force that firmly holds the two plates together. Additional top (Item# SB1T) and bottom (Item# SB1B) plates can be purchased separately. |

NX1NF |

Indexing Mounting Base This base is ideal for redirecting a laser to multiple targets on your optical table. Applications include precise switching of shared laser systems, directing optical signals to multiple test instruments, and easy exchange of optical components (with extra top mounts). For best performance, ensure that the NX1NF is securely attached to its support structure. A series of three #8-32 (M4-0.7) tapped mounting holes are provided for mounting the bottom plate to a post or breadboard and the top plate has a single 8-32 tap for mounting optical components. |

NX1F ESK01 |

Bases and Post Holders Essentials Kit For those who are just starting out and need a little bit of everything, the ESK01 Bases and Post Holders Essentials Kit contains 130 of the most commonly used post holders, bases, and table clamps, all conveniently housed in a completely labeled cabinet. The large variety of sizes provides the maximum amount of flexibility when breadboarding an optical system. This kit is best used in conjunction with ESK03 Post and Accessories Essentials Kit. |

Insights:光学実験のベストプラクティス

こちらのページでは下記について説明しています。

- ワッシャ:オプトメカニクスに使用する場合

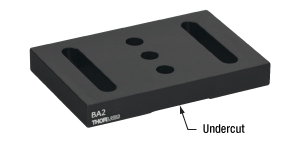

- ベースは、アンダーカットのある面を下向きに置くと安定します

このほかにも実験・実習や機器に関するヒントをまとめて掲載しています。こちらからご覧ください。

ワッシャ:オプトメカニクスに使用する場合

Click to Enlarge

Figure 174B スロットを損傷させないよう、ボルトを挿入する前にワッシャを入れてください。ワッシャの丸みを帯びた滑らかな面をスロット側に向けて置き、フラットな粗い面がボルト頭部と接触するようにします。滑らかな面は、アルマイト処理された表面を傷つけることなく、容易に移動できるように設計されています。上の図はベースBA2(/M)です。

Click to Enlarge

Figure 174A ワッシャの直径はボルト頭部より35%大きくなっています。これによりベースBA2(/M)のスロットにオーバーラップする面積はボルトの6倍になります。ワッシャはボルトの力をより広い面積に分散することで、スロットがえぐられるのを防止する役目をはたします。

標準的なキャップスクリュの頭部は、ネジの外径よりもそれほど大きくはありません(Figure 174A)。例えば1/4-20"ネジの頭の径は0.365~0.375インチ(約9.27~9.53 mm)で、このネジ用の貫通穴の径は0.264インチ(約6.71 mm)です。

デバイスを固定するためにネジを直接貫通穴に入れて締め付けると、力が貫通穴のエッジ部分にかかり、ネジでデバイスのエッジ部分をえぐってしまう場合がよくあります(Figure 174A)。

このエッジ部分が恒久的に変形してしまった場合、ネジの頭はえぐられた溝に戻ろうとするため、デバイスを精密に調整しようとしても、デバイスは元の位置に戻ってしまいます。

円形の貫通穴の場合は、ネジに対してデバイスを移動させようとするものではないので、このような変形による問題は生じないことが期待できます。

しかしスロットの場合には、スロットに沿ってどの位置にでもデバイスを固定できなければなりません。ワッシャを使用すると、力がスロットのエッジから離れる方向に分散されるので、スロットが変形しにくくなります。Figure 174Aでは、ワッシャがもたらす効果を図示しています。ベースBA2/Mのスロットと頭の径が0.37インチ(約9.4 mm)のキャップスクリュの接触面積は0.010 in2(約6.5 mm2)です。径0.5インチ(12.7 mm)のワッシャを使用すると接触面積は0.064 in2(約41.3 mm2)となり、6倍ほど大きくなります。

当社のワッシャには、それぞれの面に特徴があります(Figure 174B)。1つの面はフラットで粗く、もう1つの面は丸みを帯びていて研磨されています。丸みを帯びた研磨された面を、アルマイト処理されたデバイスの面に向けて置いてください。

ネジを締め付けるときに、ネジの頭でワッシャがアルマイト処理された面に対して回転する場合があります。

フラットで粗い面をアルマイト処理された面に押し付けた場合、摩擦でその表面を傷つける場合があります。しかし、丸みを帯びた面を接触させた場合、滑らかな面による摩擦は小さいため傷がつきにくく、デバイスの外観がより長く保たれます。

最終更新日:2019年12月4日

ベースは、アンダーカットのある面を下向きに置くと安定します

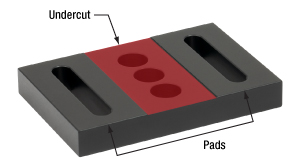

アンダーカットはBA2/Mのようなベースの下側の面に機械加工されます(Figure 174CとFigure 174D)。アンダーカットによりパッドと呼ばれる脚ができます。最大限の安定性を得るため、パッドがテーブルやブレッドボードに接触するようにベースを置いてください。

ベースの上側の面にはアンダーカットは無く、部品取付け用の面になっています。

ベースを上下逆に取り付けると、ベースがテーブルやブレッドボード上で動いたり、その他の機械的な不安定性が生じたりする場合があります。

パッドの平面度

パッドの平面度を向上させる鍵はアンダーカットです。パッドは、アンダーカットの加工後に平面加工されます。

この工程で生じる摩擦熱でパッドが加熱され、平面度はそれによって影響をうけます。アンダーカットでパッドの表面積を小さくすることで、この工程での発熱量が抑えられます。

機械加工においては、発生する熱を最小限に留めることは有益です。金属は加熱されると膨張しますが、機械加工中に発生する不均一な加熱により、部品の寸法が歪む場合があります。加工中に部品の寸法が歪むと、冷却後の部品には高いスポットやその他の望ましくない形状が残る可能性があります。そのような部品を使用すると、不安定性やミスアライメントにつながる場合があります。

精密な機器やデバイスのパッド

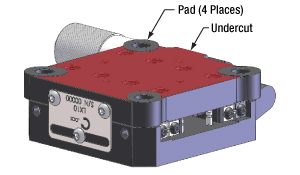

パッドの付いたほかの例として、Figure 174Eに直線移動ステージLX10(/M) を示します。

Click to Enlarge

Figure 174E 適切な安定性を得るため、ベースはアンダーカットがある面を光学テーブルまたはブレッドボードに向けて取り付けてください。

Click to Enlarge

Figure 174D この図はベースの下側を示しており、赤く表示された箇所がアンダーカットです。この部分を切除することで、極めて平坦なパッドを実現できます。

Click to Enlarge

Figure 174C 適切な安定性を得るため、ベースはアンダーカットがある面を光学テーブルまたはブレッドボードに向けて取り付けてください。

最終更新日:2019年12月9日

| Posted Comments: | |

| No Comments Posted |

Products Home

Products Home

Mini-Series Slotted Bases

Mini-Series Slotted Bases